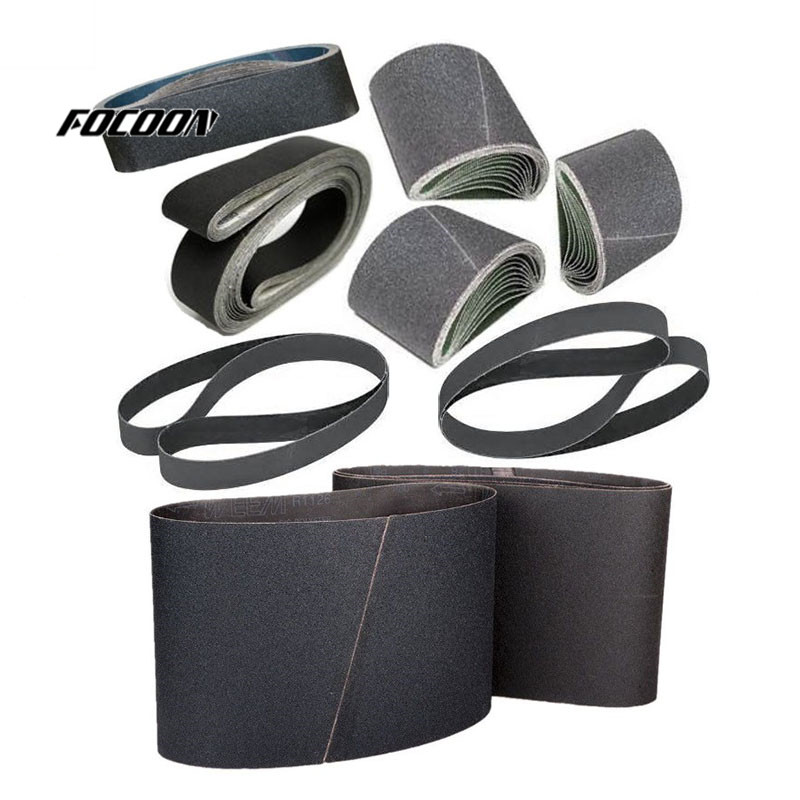

Ibhanti yesanti ye-silicon carbide Ilaphu okanye iPhepha elixhasayo limanzi kwaye lilomile

Yiba nokusebenza

Isetyenziswa kakhulu ekusileni nasekupholiseni iipleyiti ezahlukeneyo zomthi, intsimbi, ubhedu, i-aluminiyam, ingxubevange, iglasi, iintsimbi ezingezizo ezoni, iiseramikhi, i-porcelain, iiminerali, ilitye, irabha, kunye nezinto ezenziweyo.Inomsebenzi wokumelana nobushushu kunye nokungangeni kwamanzi, okufanelekileyo ukugaya okomileyo, kwaye kunokongezwa kunye nokupholisa.Umphezulu wesanti ubukhali, unamandla amakhulu kakhulu kunye nokukwazi ukugawula, ukulungele ukugaya amacwecwe aphakathi kunye noxinzelelo oluphezulu, kwaye ingasetyenziselwa ukulungiswa kakuhle kweendawo zetsimbi, ezinokufikelela kwimiphumo emihle.Kumsebenzi orhabaxa, ophakathi kunye nokugqiba komgangatho wemveliso, unokufikelela kwiziphumo ezigqwesileyo zokugaya.Isiseko selaphu sinentlupheko eyomeleleyo kunye ne-ultra-wide sub-tension, engasetyenziselwa amabhanti amakhulu abrasive.

sebenza:

Ukusila ngokuzenzekelayo, ukugaya ngesandla ngoomatshini, ukucola idesktop, isixhobo sokusila ngesandla

Yenzele okuthile:

Iinkcazo ezahlukeneyo zingenziwa ngokwezifiso ngokweemfuno zabathengi kunye nezingalinganiyo

I-Silicon carbide (i-SiC) yenziwe ngesanti yequartz, i-petroleum coke (okanye i-coke coke), kunye ne-wood chips ngokusebenzisa ubushushu obuphezulu bokunyibilika kwisithando somlilo.

Kubandakanya i-silicon carbide emnyama kunye ne-silicon carbide eluhlaza:

I-silicon carbide emnyama yenziwe ngesanti yequartz, i-petroleum coke kunye ne-silica ekumgangatho ophezulu njengeyona nto iphambili, kwaye inyibilikiswa kubushushu obuphezulu kwiziko lokumelana.Ubunzima bayo buphakathi kwe-corundum kunye nedayimane, amandla ayo omatshini aphezulu kune-corundum, kwaye i-brittle kwaye ibukhali.

I-silicon carbide eluhlaza yenziwe kwi-petroleum coke kunye ne-silica ekumgangatho ophezulu njengeyona nto iphambili, yongeza ityuwa njengesongezo, kwaye inyibilika kubushushu obuphezulu kwiziko lokumelana.Ubunzima bayo buphakathi kwe-corundum kunye nedayimane, kwaye amandla ayo omatshini angaphezulu kwe-corundum.

I-silicon carbide abrasives esetyenziswa ngokuqhelekileyo ineekristale ezimbini ezahlukeneyo:

Enye yi-silicon carbide eluhlaza, equlethe ngaphezu kwe-97% ye-SiC, esetyenziselwa ikakhulu ukucola izixhobo ezinegolide eziqinileyo.

Enye yi-silicon carbide emnyama, ene-metallic luster kwaye iqulethe ngaphezu kwe-95% yeSiC.Inamandla amakhulu kune-silicon carbide eluhlaza kodwa ubunzima obuphantsi.Isetyenziselwa ikakhulu ukugaya isinyithi kunye nezinto ezingezizo ezentsimbi.Ubume be-silicon carbide emnyama i-brittle kwaye inzima kune-corundum abrasives, kwaye ukuqina kwayo kungaphantsi kwe-corundum abrasives.Kwizixhobo ezinamandla asezantsi, njengezinto ezingezizo ezentsimbi (iipleyiti ezahlukeneyo ezifana neplywood yomthi, i-particleboard, i-high, medium and low density fiberboard, ibhodi ye-Bamboo, ibhodi ye-calcium silicate, isikhumba, iglasi, i-ceramics, ilitye, njl. iintsimbi ezingenayo i-ferrous (i-aluminiyam, ubhedu, ilothe, njl.) kunye nezinye izinto ezilungele ukulungiswa.Ikwayinto efanelekileyo yokuqhobosha ukuze kusetyenzwe nzima kunye nemathiriyeli enqabileyo.

Ubungakanani benkozo ye-abrasive yebhanti ye-abrasive inempembelelo enkulu kwimveliso yokusila kunye nobunzima bomhlaba wokucubungula.Ukuze kuqinisekiswe uburhabaxa kunye nokusebenza kakuhle kwe-workpiece, kufuneka isekelwe kwiimfuno ezahlukeneyo zokulungiswa, ukusebenza kwesixhobo somatshini, kunye neemeko ezithile zokucubungula, ezifana nesibonelelo sokulungisa i-workpiece, isimo somphezulu, izinto eziphathekayo, unyango lobushushu, ukuchaneka, uburhabaxa bahlukileyo ukukhetha amabhanti egrit ahlukeneyo.Ngokuqhelekileyo, igrit erhabaxa isetyenziselwa ukugraya kwaye igrit ecolekileyo isetyenziselwa ukucola kakuhle.(Le datha ilandelayo yereferensi kuphela, kwaye iimeko zangempela zokucubungula zihambelana nokusebenza kwesixhobo somatshini kunye neeparitha zokucubungula, njl.)

| Ubungakanani beenkozo ezibolileyo | Ukusetyenzwa kokuchaneka koluhlu |

| P16-P24 | Ukusila ngokurhabaxa kwe-castings kunye ne-weldments, ukukhupha izinyusi, ukudanyaza, njl. |

| P30-P40 | Ukusila ngokurhabaxa kwezangqa zangaphakathi nangaphandle, iindawo ezisicaba kunye neendawo ezigobileyo Ra6.3~3.2 |

| P50-P120 | Ukusila ngendlela echanekileyo, ukucolwa kakuhle kwezangqa zangaphakathi nezingaphandle, imiphezulu ethe tyaba negophe Ra3.2~0.8 |

| P150-P240 | Ukugaya kakuhle, ukwenza ukugaya iRa0.8 ~ 0.2 |

| P250-P1200 | Ukuchaneka kokusila Ra≦0.2 |

| P1500-3000 | Ukuchaneka okuphezulu kokusila iRa≦0.05 |

| P6000-P20000 | Ultra-precision machining Ra≦0.01 |